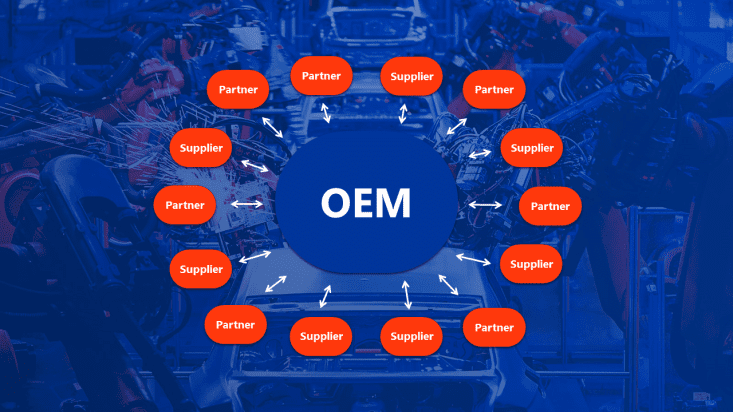

The ever-evolving automotive industry, characterized by its complex engineering and intricate supply chains, poses a unique set of challenges for OEMs when working with suppliers and partners. While these challenges are distinctively underlined in the automotive industry, they are by no means limited to this domain and are equally significant in any industry dealing with complex engineering products.

In our recent ShareAspace Forum 2023, we closely examined the top five challenges that the automotive industry faces in its collaboration with suppliers and partners. This insightful exploration was further supported by a detailed report on industry trends by CIMdata. Let’s dive deeper into these challenges and discover how ShareAspace, our collaboration hub, can be the solution of choice.

Five big challenges

Here are the top 5 challenges:

- Quality Control: The automotive industry demands extremely high levels of quality control and precision. Suppliers and partners must adhere to stringent standards to ensure the safety and reliability of the vehicles they produce.

- Cost Management: The automotive industry is highly competitive, and cost management is a key factor in profitability. Suppliers and partners must be able to deliver high-quality components at competitive prices to remain viable.

- Supply Chain Disruptions: The automotive industry is vulnerable to supply chain disruptions, such as shortages of critical components or delays in delivery. Suppliers and partners must be able to manage these risks to avoid production delays and lost revenue.

- Intellectual Property Protection: The automotive industry is highly innovative, and suppliers and partners must protect their intellectual property to remain competitive. This can include protecting trade secrets, patents, and trademarks.

- Regulatory Compliance: The automotive industry is heavily regulated, and suppliers and partners must comply with a wide range of regulations and standards, from safety and environmental regulations to labour laws and trade restrictions. Non-compliance can result in legal penalties, reputational damage, and lost business opportunities.

In response to these challenges, companies are investing in PLM software to improve their business processes. With this investment, companies expect faster, cheaper, and better processes. When working with hundreds of partners, even small improvements can lead to significant cost savings and efficiency gains.

Different types of collaboration

During the ShareAspace Forum we talked about three different types of collaboration—system purchase, build-to-print, and co-engineering. From a high-level viewpoint, they are all very similar in that it is engineering data that is being shared between an OEM and its supplier(s). Sometimes data is also complemented by more details from one or the other party. However, the sharing of information between OEMs and their suppliers is crucial for the performance of the partnership, and this process can be quite complex and nuanced.

It’s important to have a reliable, efficient method of communication and data exchange to ensure smooth collaboration. The overall challenge of running a conversation, in the context of engineering information, with hundreds of counterparts in parallel is the perfect storm for accumulating errors. This is the kind of problem ShareAspace is designed to solve.

What is ShareAspace?

Think of ShareAspace as an ‘Information Loading Bay.’ Here, manufacturers can check data before using it in their systems. By automating this process, ShareAspace saves time and boosts productivity.

With a focus on sustainability and initiatives like the Digital Product Passport, manufacturers need to maintain a complete digital record of their products. As more tasks move to external partners, this responsibility extends across the supply chain. ShareAspace helps collect and maintain this information over time.

Magnus Färneland, our Director of Manufacturing industry vertical, sums it up: “We guide our clients on their digital transformation journey and add crucial information to the product’s digital thread.”

ShareAspace is more than just a tool for supply chain collaboration. It’s part of the digital transformation journey, enriching the product’s digital thread and enabling companies to navigate automotive industry challenges with greater confidence.

To watch the full presentation including the latest demo of ShareAspace Design to Manufacturing, click here.