Posting this as a blog on the Eurostep web site but you can follow the discussion on Linkedin here. PLCS is not needed for a digital thread but it is a very good and rich information model and designed as such, not the result of M&As within a PLM vendor. So, in our view a pretty good candidate as the foundation of a digital thread. And if the standard is good it does not hurt that it is standard, as one of the biggest concerns with PLM is classic vendor lock in.

Below is a recent reply in the Linkedin thread, from Rob Bodington, Eurostep, good for all to read.

In my view there are two significant features of PLCS (see: http://www.plcs.org/plcslib/plcslib):

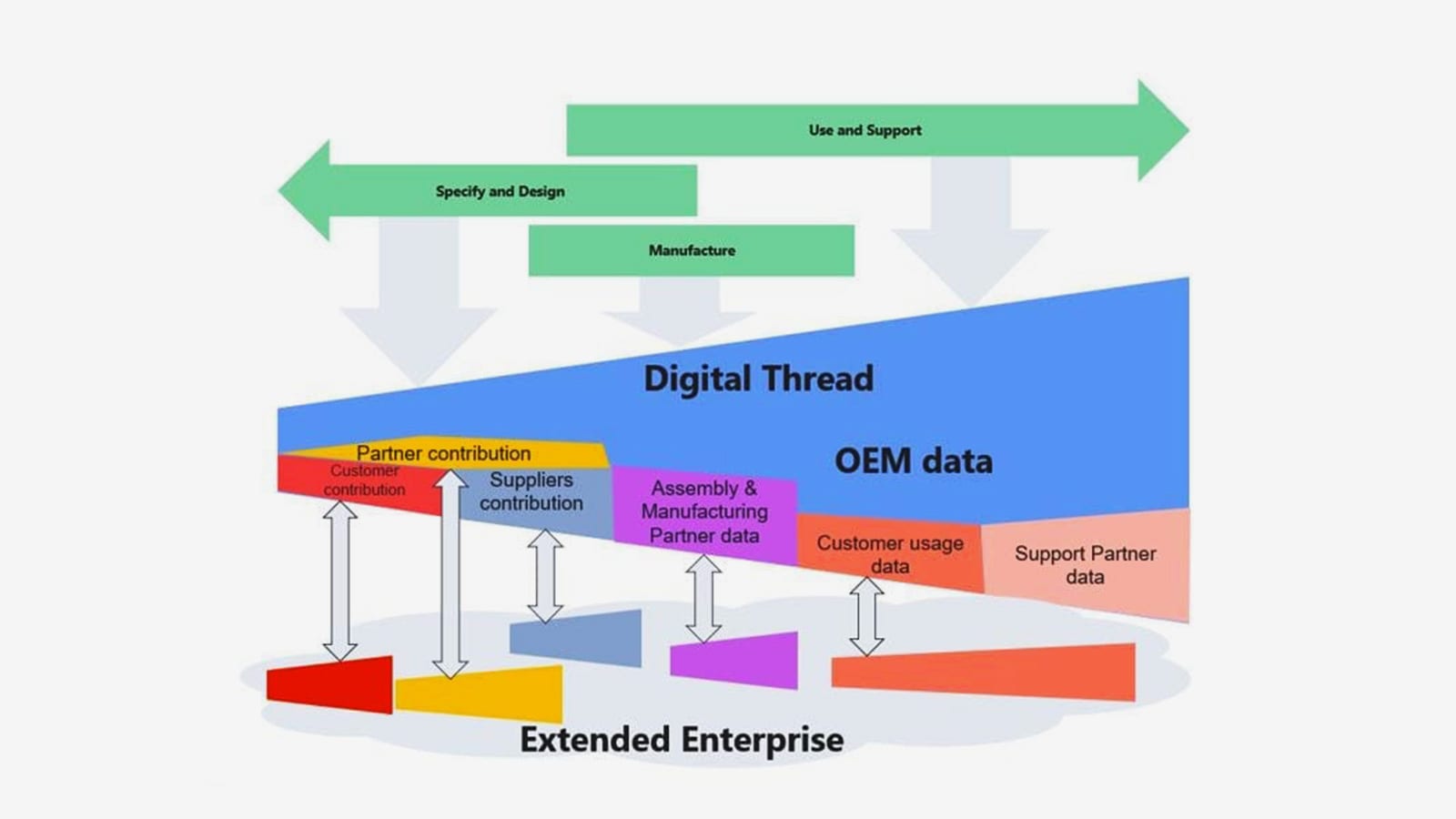

1) An information model for managing product data through life, from early stage conceptual design right through to in-service and disposal This for me is the most valuable feature of PLCS. It is a model that, when implemented in software, such as ShareAspace, enables the management of the digital thread. For example, you can achieve full traceability from requirements changes, through to design changes, to modification instructions through to the configuration of individual vehicles currently operating.

2) Standards based data exchange. PLCS provides for the specification of a data exchange (DEX). This is useful for precisely specifying “what” data to be exchanged “when”. The uptake of PLCS for data exchange has been limited and mainly used in defence procurement. I find the limited uptake surprising considering the proliferation of data quality and exchange challenges throughout product life cycle. Where DEXs have been successful, they have been explicitly called out in commercial contracts. That avoids ambiguous statements.