Managing unstructured and structured product data

We are living in the age of digital transformation and IT is becoming an integral part of our lives. Design and engineering of things is today digital but the change in recent years is in the digitalization of our interaction with all “real things” and services.

For a long time, we have used highly structured information in databases to manage information about the definition and state of our “life-supporting” systems like apartments, cars, airplanes etc. In this paradigm most, but not all, of the synthesis of our observations has been done

by humans and our cognitive processes. The technology for automated feedback has been developed per case and has not been scalable. A lot of valuable knowledge about the use of products and customer experience has been “lost” as high-quality data capture and feedback from the field has been too complex, expensive and not at all scalable.

The structured world has lived mainly disconnected from the real physical world with all its issues to collect data.

With the (still emerging) IoT explosion the observation process is digitalized using machine-generated data from intelligent or non-intelligent devices. Social listening can also be used with feedback mostly on the type level of a product and not on the serialized item. All of the above will generate a huge amount of observation data. It is not possible anymore to analyze and make synthesis without the use of digital systems. Human cognitive processes will need to be replaced by rule-based digital processes.

So now, the structured and unstructured worlds are both digital. But they are still disconnected.

To be able to define what to look for in the data stream of IoT devices, rules need to be defined. To be able to create the rules you ideally need to know what you are looking for, the rules are based on the expected faults. Once this is in place the two digital worlds can connect.

However, not all events map with expected ones. In fact, what we can measure today in raw data might not be useful today but possibly tomorrow and in the future. But we keep on collecting raw data in data lakes without mining them for value. There is potentially a very valuable source of information in the raw data if it can be put in the context of their relations in the world of structured product definitions.

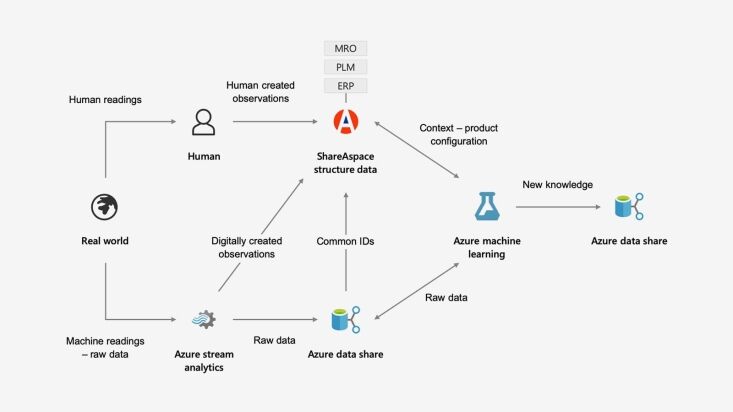

In order to be able to benefit from the potential value we need to store the raw data in data lakes with ID references into the structured world in parallel to the structured data in the databases.

By applying machine learning to the combination of the life cycle information of the product (structured data) and the raw data in the data lake (unstructured), conclusions can be drawn and fed back to the structured data world for reuse in product design, maintenance planning and usage.

The value of a Digital Twin is dependent on the degree to which it reflects the state of the product and its components in every moment of its lifecycle including its configuration. The Digital Twin of the product in use can in itself be valuable for the maintenance and management of a fleet or installed base. But it will be much more powerful when this data can be fed back to stages when manufacturing and design decision were taken, decisions with high impact on overall life cycle cost. This will empower the digitalized learning enterprise.

The combination of ShareAspace software based on PLCS (ISO 10303-239 Product Life Cycle Support standard) and Azure Data Lakes, Stream Analytics and Machine learning fulfils all these requirements and is a superior foundation for the realization of high-quality Digital Twins.

ShareAspace will be the hub bridging the unstructured data from the real world to the structured data in MBSE, PDM, ERP and MRO systems.