Introduction – The purchasing of complex components

Operational purchasing of complex components is a challenge for many companies.

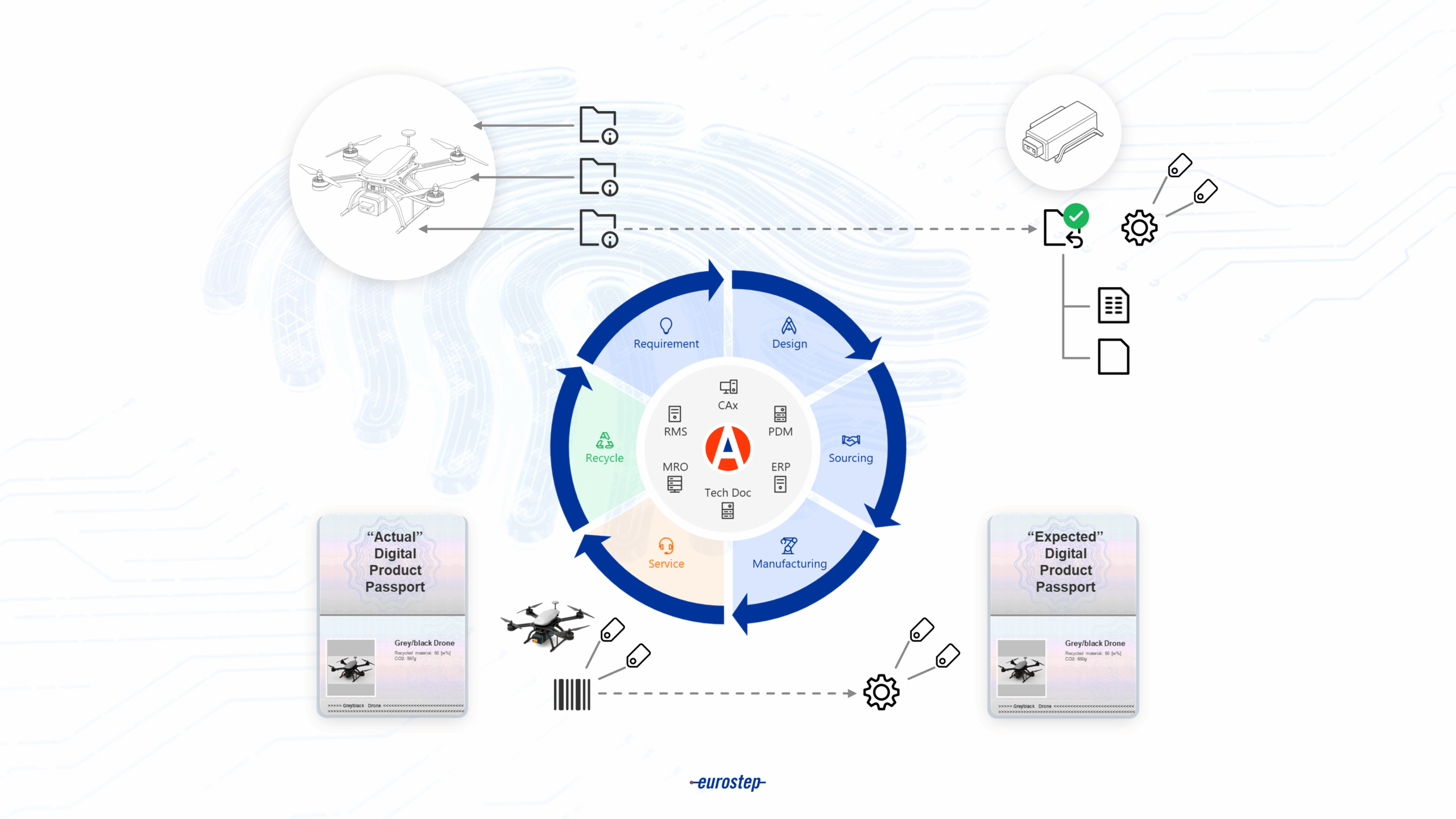

Complex products are usually assembled from complex components. Today, the OEM of a complex product like a car, an aircraft, or a power plant typically purchases complex components from several suppliers. The quality of the final product depends on correctly specifying all components and then manufacturing and delivering them as specified.

The component’s definition is usually based on a standard offering and configured for the specific project or product. The standard offering typically changes over time, and the specification of the specific component does the same. The specification of the complex component is, by nature, complex and is usually managed in a PLM tool.

A crucial part of a successful purchase is having a common understanding with your suppliers on what component to deliver, taking into account the original definition and any changes that will occur. Other areas to address include when to deliver, where to deliver, required certificates, required documentation, and pricing.

The complete purchase process involves many roles such as engineering, purchasing, logistics, and more that define the overall product and the specification of the components. Operational purchasing agrees on and issues the purchase order, project/manufacturing management sets time and cost restrictions and a lot more goes on.

The purchasing process will involve at least one supplier per component but in many cases several. Purchasing requires the transfer of information defining the complete purchase as described above. Before digitalisation, this was managed by sending paper drawings including all information required to define the product along with an RFQ/PO paper document adding the commercial parts. This way of working had some advantages, as it managed to capture the information in one container (the drawing) in a neutral format (paper drawings). Responses were then sent in the same way.

The typical situation today is…

Download our whitepaper to learn more: