In an age defined by technological leaps and bounds, Product Data Management (PDM) has evolved from being a mere digital vault for CAD files to an indispensable tool for competitive advantage. Its transformation signifies not just an evolution but a revolution, which is crucial for companies striving to stay ahead in a global market.

From simple repositories to robust systems

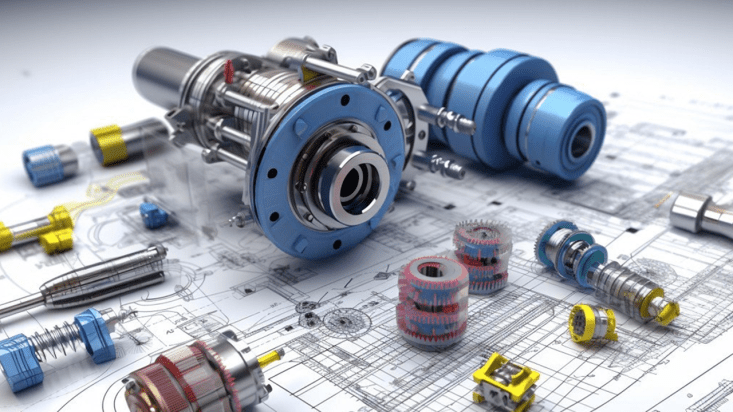

Initially, PDM served as a basic storehouse for CAD drawings and related documents. It was a step up from physical storage but had limitations. Today, PDM has matured into a comprehensive system that acts as an organizational linchpin—a single source of truth that ensures data integrity and enables real-time collaboration across departments.

Beyond CAD: Managing diverse digital assets

Today’s PDM systems are not just about CAD files anymore. They manage a wide array of digital assets, from 3D models and software scripts to multimedia files and documentation. This aligns seamlessly with the multifunctional teams that are the norm in modern workplaces.

Fostering cross-departmental synergy

Modern PDM systems allow for real-time collaboration across various departments, whether it’s Engineering, Sales, or Marketing. With centralized data storage, everyone has immediate access to the most recent and relevant information. This speeds up decision-making and minimizes errors, translating into cost efficiency.

Ensuring version control and traceability

Sophisticated version control is a significant advancement in modern PDM systems. This feature ensures that all team members access the most recent file versions, eliminating conflicts and redundancy. Moreover, audit trails provide a transparent record of all changes, making compliance with industry standards and regulations more straightforward.

The unseen power of metadata

Metadata, the information that describes other data, has become crucial in contemporary PDM systems. By attaching relevant metadata to assets, users can effortlessly search for and retrieve necessary information. This expedited access speeds up project timelines and prevents the loss of valuable data in complex systems.

Prioritizing security and compliance

Modern PDM systems incorporate advanced security measures to protect sensitive information. Specialized compliance modules help organizations meet industry-specific regulations, whether it’s FDA guidelines in the pharmaceutical industry or ITAR compliance in the defence sector.

Integration with Product Lifecycle Management

Looking ahead, the role of PDM systems will expand, integrating more closely with overarching Product Lifecycle Management (PLM) platforms. While PDM focuses on data management, PLM takes a more comprehensive view of a product’s entire lifecycle. This holistic approach facilitates the seamless flow of information throughout an organization, creating more opportunities for innovation and adaptability.

In summary

The transformative journey of Product Data Management showcases the disruptive impact of technology on traditional systems. From its rudimentary role as a CAD file store, PDM has blossomed into a critical system that straddles data management, collaboration, and digital transformation. As it continues to merge with broader PLM systems, the scope for innovation and efficiency is boundless.