Key points:

- Eurostep is working with a consortium of partners on the “Demonstration of Infrastructure for Digitalization Enabling Industrialization of Additive Manufacturing” (DiDAM) project to enable product traceability and support full-scale Additive Manufacturing industrialization.

- Eurostep’s ShareAspace PLM collaboration platform is being used to connect lifecycle data to digital models and expand its capabilities, including Digital Rights Management on product data to protect Intellectual Property.

- The project seeks to address the challenge of enabling safe and secure value chains, including the efficient flow and secure access to digital information among involved actors, as well as the ability of new actors to share and exchange digital information.

- The project is part of the Produktion2030 initiative, which aims to renew and strengthen Swedish industry competitiveness through innovative knowledge, strong collaboration, and cutting-edge technology.

How can I deliver products and spare parts to my clients around the world in an agile way?

In one of our previous blogs, we talked about the need to support more sustainable product designs regardless of any disruption in the supply chain. However, disruptions in tightly integrated supply chains have demonstrated that delivering in a lean manner could prove to be fragile. Resulting in the need to rapidly source new suppliers and consequently increasing the dynamics of value chains. Additive Manufacturing (AM) enables highly optimized product designs to be produced with minimal waste compared to traditional subtracting manufacturing. At Eurostep we are looking to expand our solution for such needs. One of the projects we are collaborating on is called “Demonstration of Infrastructure for Digitalization enabling industrialization of Additive Manufacturing” (DiDAM). As its name implies, the goal is to demonstrate a state-of-the-art solution for industrializing Additive Manufacturing effectively. Enabling traceability of products by connecting lifecycle data to digital models, including AM materials and processes involved.

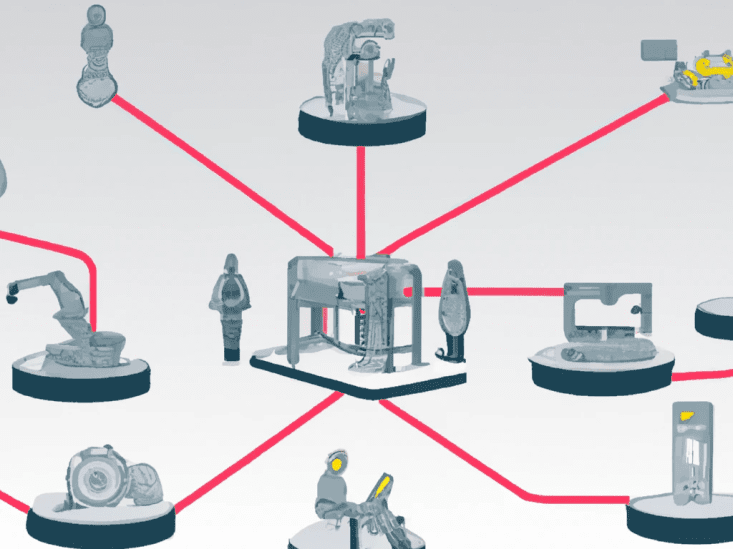

What underpins our involvement in DiDAM are the existing capabilities of our ShareAspace PLM collaboration platform. ShareAspace enables partners to share product data in a few clicks, collaborate using state-of-the-art security while having a personal workspace, allow full data traceability and change impact overview. As Bonham et al. mentioned, AM provides an opportunity for decentralized production, as the product can be manufactured near the customer wherever an AM machine is located. Minimizing the time, cost and emissions associated with the delivery of the product. Eurostep is aligning with DiDAM goals as AM will continue bringing new partners and suppliers of material, software, and equipment into a production environment. Expanding the current capabilities of ShareAspace to include Digital Rights Management on product data, protecting Intellectual Property and controlling the usage of such information to support full-scale industrialization of AM. However, there are several requirements that need to be addressed to enable safe and secure value chains. Starting with enabling efficient flow and secure access to digital information among the involved actors. This is followed by enabling new actors to effectively share and exchange digital information to enable efficient production, repair and remanufacturing of next-generation products.

Eurostep is collaborating in DiDAM along with a strong consortium of partners. Industrial manufacturers represented by AB Volvo and Epiroc are leading manufacturers in industrializing AM and are providing industrial use cases for the project. These use cases will support, from a digital point of view, the definition of the needs by providing insight on the challenges faced when integrating AM. Brogren Industries is also one of the involved partners, they are one of the approved machining and sub-suppliers in Sweden to the Aerospace industry. Uddeholm will contribute as the AM material and powder provider for the project. Chalmers, leading the project, provides research and educational expertise in digitalization for collaborative engineering and digital platforms for AM. It also provides expertise and printing resources via the MANUELA (EU) project, ensuring demonstrations with both physical and digital demonstrations. In addition, RISE IVF will contribute to the project as one of the leading AM research teams in Sweden with a strong focus on the entire supply chain for AM. They previously coordinated both DISAM and DILAM projects similar to DiDAM. Value-chain and PrintSyst are also partners bringing competence and solutions for digitalizing the supply chain as a software solution provider.

Finally, DiDAM is part of Produktion2030 which aims to renew and strengthen the competitiveness of Swedish industries through innovative knowledge, strong collaboration, and cutting-edge technology. Eurostep will continue to contribute towards the same goals and the development of technical solutions involving digital thread and digital twins as well as the involved best practices and standardization in engineering domains.

Interested to learn more about our work in DiDAM? Check out our short educational video series – DiDAM nuggets.

Executive summary

Eurostep is collaborating with a consortium of partners in the “Demonstration of Infrastructure for Digitalization Enabling Industrialization of Additive Manufacturing” (DiDAM) project to deliver products and spare parts to clients all over the world in an agile manner. Eurostep intends to enable product traceability, expand the capabilities of ShareAspace, and support full-scale industrialization of Additive Manufacturing by connecting lifecycle data to digital models via their ShareAspace PLM collaboration platform. The project addresses the challenge of enabling safe and secure value chains by facilitating the efficient flow and secure access to digital information among involved actors, allowing new actors to share and exchange digital information, and addressing decentralized production requirements.